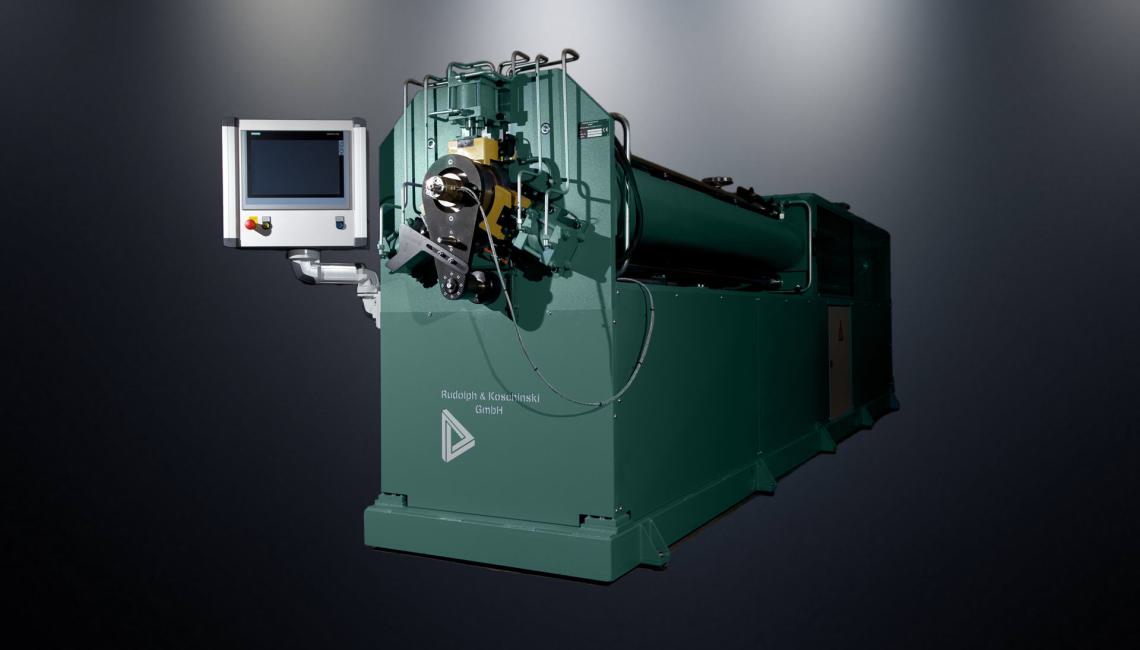

Technical data PTFE Paste / Ram Extruder Type PEX

The centerpiece of all PTFE product facilities is the paste or ram extruder. Pricipally the machine consists of a cylinder, which is being loaded with the PTFE preform. In case of cable production the conductor is fed through the middle of the cylinder (through the mandrel bar). A piston is moved by haudraulic force of 50 tons of pressure through the cylinder, thus resulting in the PTFE material being pressed to the extruder head. Here a pressure of 1300 bar arises, under which the PTFE plastifies and flows into the tools which form the sheath around the conductor, creating the cable. Many sophisticated construction details make sure, that there occur no imbalances and therefore minimal tiltings within the process, resulting in very high centricity values of up to 92%. The operation of the line is conducted by an individually configurable, graphic panel, where all relevant information on line status and current production task are shown and can be manipulated. The head of the extruder swivels automatically open and to the side and offers a loading support, so that the machine operator comfortably and precisly can load the PTFE preforms into the machine.

- Extrusion cylinder

length: up to 3000 mm

standard diameter: 64mm

compression stroke: 75t

cylinder can be changed, further available diameters: 42 - 80 mm - Loading volume: 3 x preform according to cylinder length

- Mandrel bar adjusted to mandrel bar of preform press

- Working height: 1350mm

- Drive:

hydraulic cylinder with combination sealing gasket

valves Bosch/Rexroth - Extruder head:

made from special material

opening / closing - clamping and panning hydraulically controlled. - Mandrel bar adjustment: through regulated spindle drive with shaft joint with position acquisition.

- Extruder driving through electronically regulated proportional valves.

- 1x nozzle heating adjusted. 1x collar heating adjusted.

- Painting: RAL according to customers wish

- Cabling according to VDE code, diagrams are supplied threefold in DIN A4

- CE conformity declaration

- Line speed: up to 60 m/min

- Accomplished cable lengths: up to 6000 m

- Conductor-Ø range: AGW 16 - 24 / especially suitable for 5Y and LiSY conductors