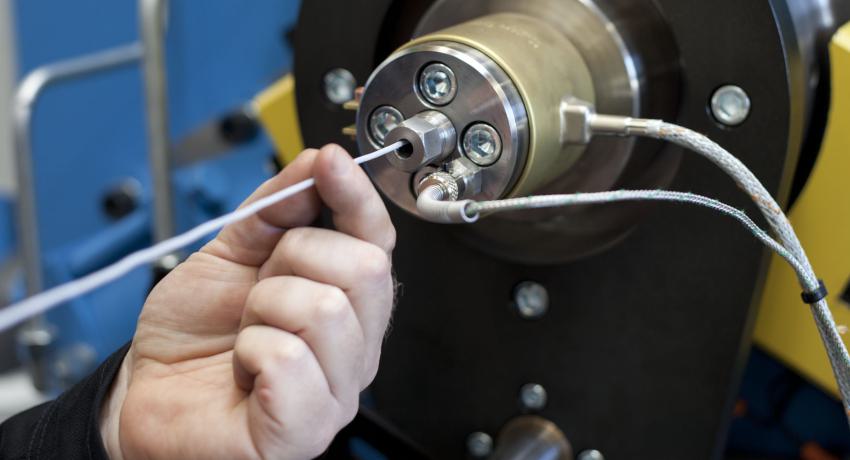

Generally the processing of PTFE is more complicated than of "conventional" raw materials. Especially the reduction ratio must be taken into account, which the producers of the PTFE raw materials purport. The reduction ratio is the ratio of cross-section of the preform to the cross section of the insulation on the wire. The reduction ratios mostly are within the range of 100 - 4000, depending on the type of PTFE.

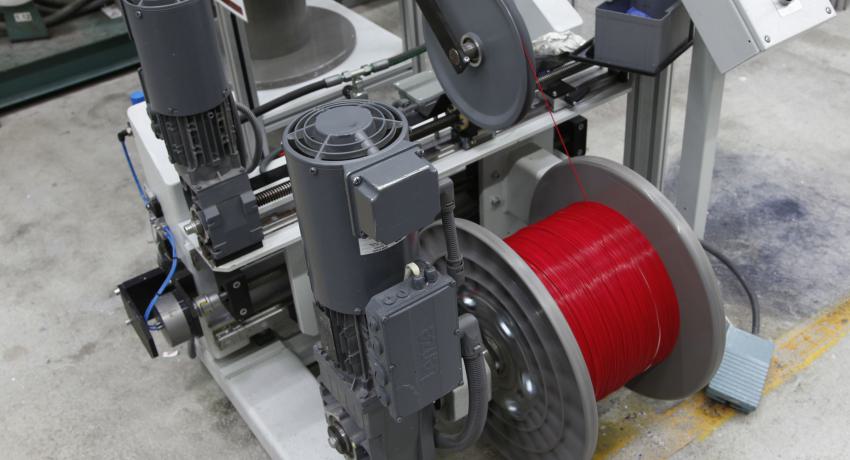

The maximum achievable running length for cable, results from the volume of the preform, which in turn results from lenth and diameter of the extruder cylinder. The volume of the preform can be "distrubuted" on the wire. Whereat you always have to consider, that the cross section of the preform must match the cross section of the insulation on the wire (see above).

As the lenth of the cylinder is predetermined due to the extruder design, the only adjustable parameter in the diameter of teh cylinder. You can use smaller as well as larger cylinders in one and the same of our machines, e.g. you can use a diameter 76 mm cylinder instead of the common 64 mm. This enables you to produce a wide range of product diameters with one machine.

For an example let us take a strand of diamerter 0,5 mm and an outer diameter above insulation of 1,2 mm. This would result in the following reduction ratios:

- Extruder cylinder 64 mm: 1:2468

- Extruder cylinder 76mm: 1:4180

Now if the recommended reduction ratio for the PTFE of our axample would be 3000, in our given example the bigger 76 mm cylinder would be above that, and thus too big.

The total length of our cylinders ranges up to 3000 mm. So you could load 3 preforms of 1000 mm each into these extruders.

However it is not possible to build any size of cylinder, just to reach higher running lengths, das always the ratio from cross-section to insulation cross-section must be considered! Typical running length are 2000 - 6000 m. The line speeds at which the cable is being produced in turn, comply with the thickness of the insulation. As the rsolvent, which is present in the PTFE raw material, must be completely evaporated from the finished product, in order to give the cable it's many positive characteristics. This evaporating process cannot be accelerated and so simply take more time as the nsulation becomes thicker. Common line speed at whcih PTFE-cable extrusion lines oprate are about 60 m/min. At very thin insulations however it would be possible to reach up to 100/min in line speed. However here are more physics and chemistry the limiting factors than the machine technics.

One of the most important characteristics of a PTFE-cable extrusion line is the centricity reached. This means how far the conductor / wire has moved out of the total center of the complete cable. The thinner the insulation wall strength becomes, the more difficult it gets to reach high centricitys. This is because, the thinner the wall thickness of the insulation, the more significant an ex-centricity becomes in proportion. At very thinn wall thicknesses it is almost impossible to reach a centricity of 92%, however even here our extrusion lines reach impressive values.

Last but not least, one has to mention that the production of PTFE-cables, compared to the processing of "conventional" raw materials is technically much more challenging. It is required that the machine operators act with great care at every single step of the production process.